Ukuzicoca isihluzi sezindlu zezindlu zamanzi ezinemathiriyeli yentsimbi

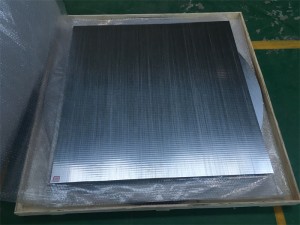

Isihluzi sokucoca ngokwakho sikwanika igama lokucoca izindlu/inkqubo yokuhluza, inomzimba othe nkqo wecylindrical, icap yokutywina, iflange, iplati yoqhagamshelo njl. Indlela yokudibanisa inokuba ziindidi ezininzi zeemilo ezifana nebhayonet kunye noqhagamshelo lomsonto. Ireyithi yokuhluza kunye nendlela yokudibanisa iyafumaneka ngokwemfuno yenkqubo yabathengi. Izinto zokucoca yi-SUS304,SUS316L\Hastelloy alloy. Umphezulu wangaphakathi uyagudiswa, ugqithiswe lulwelo lweasidi kwaye akukho angle efileyo.

Umgaqo wokusebenza wokucoca ukuzicoca

Icebo lokucoca lizakuqala inkqubo yokucoca xa umahluko woxinzelelo lwe-inlet kunye ne-outlet ifikelela kwixabiso elicwangcisiweyo. Yonke inkqubo yokuzicoca iqulethe amanyathelo amabini: ivalve yokukhupha i-valve kwi-cover yesiphelo sesihluzo iyavula; iibrashi ezimbini zentsimbi engenastainless kumnatha we-ontology ziqhutywa yimoto ngaphakathi, emva koko ukungcola okubanjwa ngomnatha kuya kuxutyushwa ngebrashi yentsimbi kwaye kuya kukhutshelwa kwivalve yokuhambisa. Yonke inkqubo yokucoca ithatha malunga nemizuzwana eyi-15 ukuya kwengama-60. ngeli xesha, inkqubo yokucoca ayiyeki kwaye yonke inkqubo yokusebenza igqitywe ngebhokisi yolawulo.

Ngeneza

Khusela impilo kunye nokhuseleko lwabasebenzisi bakho Ngesixokelelwano esivaleleke ngokupheleleyo, akukho mveliso iyingozi enjengomsi inokubaleka ngelixa ikwanciphisa ukuvezwa komsebenzisi kwiimveliso zakho ezingamanzi.

Yandisa amazinga akho emveliso – Ngoyilo lwayo lokuzicoca akukho zithintelo zokutshintsha imidiya yokucoca, okukhokelela ekuhluzweni okuhambelanayo nokuthembekileyo.

Phucula umgangatho wemveliso yakho – Inkqubo evaliweyo isusa umngcipheko wongcoliseko olungena kumgca wakho wemveliso.

Ukunciphisa inkcitho kunye neendleko zokusebenza -I-self-coca filtering isusa isidingo sokutshintsha i-media media kunye neendleko zokulahla, ukunciphisa inkunkuma yemveliso, iindleko zabasebenzi kunye nexesha lokuphumla.

isicelo

1. Intsimbi: isetyenziselwa ukucocwa kokucoca amanzi kwintsimi yezinto eziluhlaza, isityalo se-sintering pellet, ukupholisa amanzi okupholisa isithando somlilo, i-rolling mill, umatshini oqhubekayo wokuphosa kunye nezinye iinkqubo, kunye nokucoca ukungcola kwenkqubo yokususwa kwe-phosphorus yamanzi.

2. Iimoto: imigca yokuvelisa i-coating isetyenziswa ngokubanzi kwiinkqubo zokucoca amanzi kwiimoto, iitrektara, izithuthuthu kunye neenjini.

3. Iplanti yamandla: Isetyenziselwa ukuchaneka kwendawo yokulungiswa kwamanzi ahlambulukileyo aphezulu kwiibhoyila zeplanti yamandla, ukuhluzwa kwamanzi okupholisa i-generator kunye nokutywinwa kwamanzi, kunye nenkqubo ye-13-4 ingasetyenziswa njengesihluzo esisecaleni xa amanzi. ukusetyenziswa kukhulu kakhulu.

4. Ishishini le-petrochemical: kwintsimi yamanzi ejikelezayo yokucoca i-filtration yecala, imodeli enye okanye emininzi inokudityaniswa ngokuhambelana nonyango oluphambili endaweni yokucoca izinto zokucoca, ukunciphisa umthwalo wokucoca izinto zokucoca, ukuphepha umthamo omkhulu wokusetyenziswa kwamanzi okuhlamba kunye nokugcina iindleko. .

5. Izitiya zezolimo kunye nezixhobo zokugaya amaphepha: Kwizitshizi kunye neenkqubo zomlomo, ukuvaleka kwezixhobo kunye nokuguga okubangelwa bubumdaka kufuneka kuncitshiswe. Ngoko ke, kuyimfuneko ukukhetha ukuchaneka okuphezulu, imveliso yokucoca i-automated high-automated, umatshini, ukutya okanye enye: Ukucoca ngokuzenzekelayo kunye nokuchanekileyo ukukhusela ukuvala inkqubo yamanzi okupholisa.

| Isihluzo sokucoca iparameters jikelele | |

| Isantya sokuhamba komsebenzi | I-20-5000m3 / hUmgangatho wamanzi owahlukileyo kunye nokuchaneka kokucoca kunesantya esahlukileyo sokuhamba ngokwezifiso |

| Uxinzelelo lokusebenza | I-2bar-10bar-10barIsixhobo sempompo yeBooster inokusetwa kwindawo yokukhupha amanzi xa uxinzelelo lokusebenza lusezantsi. |

| Ubungakanani bevalve yokukhupha amanzi | 25mm; 50mm; 80mm |

| Ixesha lokucoca | 30-60S |

| Ukucoca ukusetyenziswa kwamanzi (ngamaxesha onke) | ≤5% |